manufacturing

STRENGTH

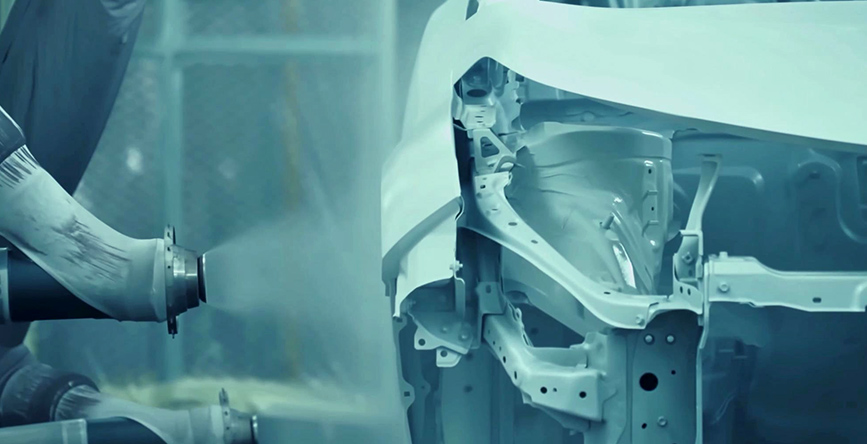

Crafting ingenuity at its origin, forging artisanal quality – JETOUR constructs intelligent, eco-friendly, and streamlined facilities through advanced manufacturing processes and stringent quality standards.

-

smart factory

Automated robots undertake over 83% of the welding work, covering over 90% of part handling and inter-station transportation. All car bodies are fully sealed and glued automatically, with an average of 120 seconds to complete the welding of a car, creating the most autonomous industrial robot intelligent manufacturing production line.

-

green factory

By using environmentally friendly B1B2 water-based paint and advanced wheel concentrator and RTO/RCO incineration process, it effectively removes VOC components from the exhaust gas, with a removal rate of up to 99%. This maximally reduces the pollution of exhaust gas to the environment, creating a green ecosystem for people, cars, and life.

-

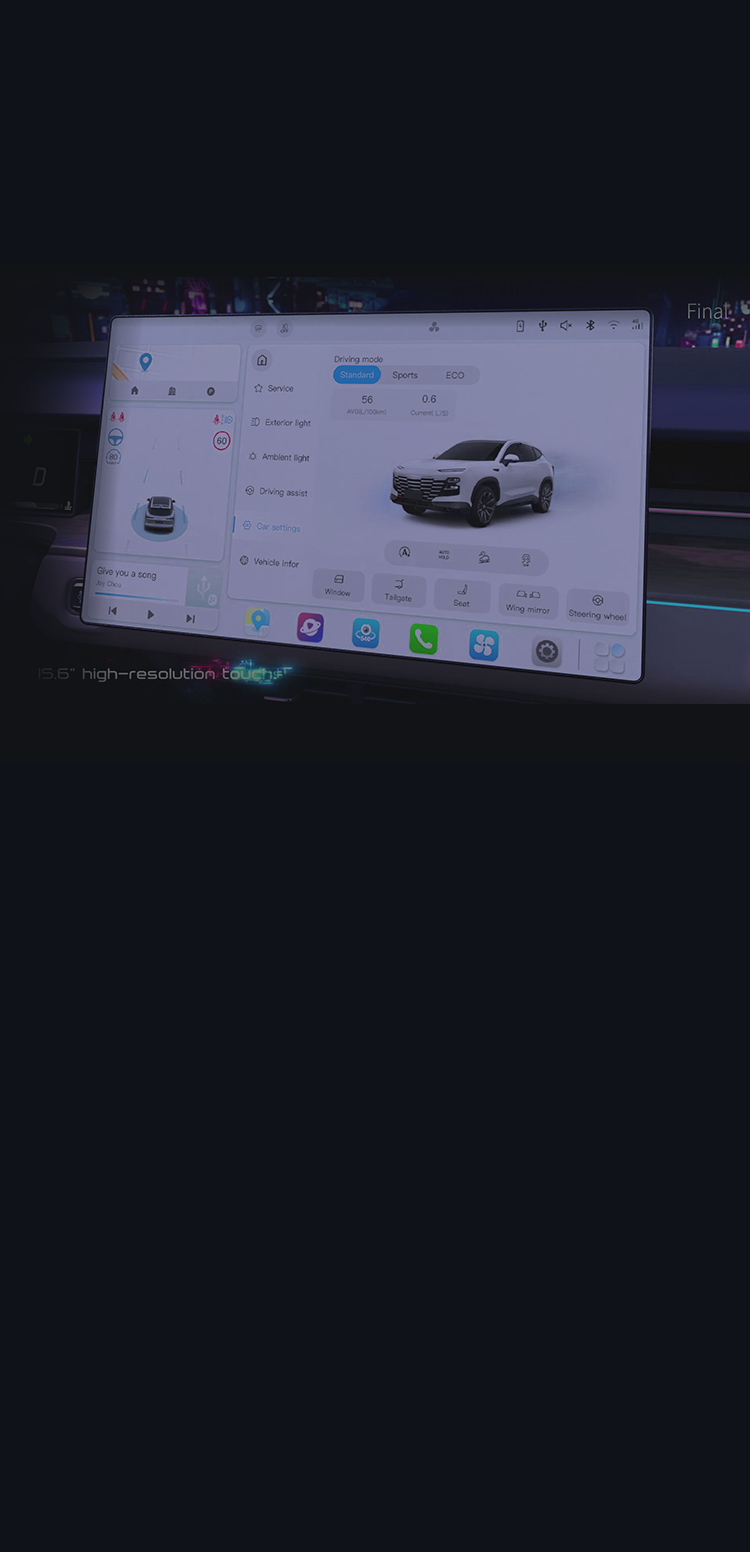

lean factory

By collecting all real-time data from the production process through a vast array of sensors spread throughout the entire factory, it achieves the vertical integration of ERP data down to the sensor level at the workshop equipment layer. It also achieves horizontal integration from product development to after-sales service, establishing an industry chain collaboration platform.